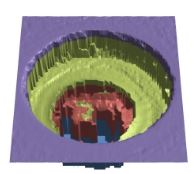

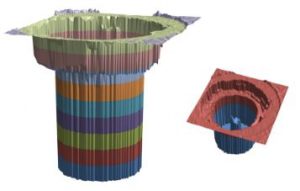

Testronics – Model 603d – 3D Backplane Prifiling & Inspection System

TESTRONICS PROFILING SYSTEM

The Testronics system does not have the disadvantages of the X-Ray systems. This is because no images are taken and no AOI

algorithms are used. Instead, the Testronics system uses a non-contact line scanner to create a 3 dimensional map (profile) of the

backplane, connectorpins and connector holes. The height of each connector pin as well as its depth into the hole is mapped (profiled).

Because the Testronics system measures the actual height and depth of each pin, defects can be detected quickly and repeatably.

Defects Detected :

– Missing pins

– Bent under pins

– Broken pins

– Bent male pins

– Wrong depth pins

– Wrong height pins

– Wrong or missing backdrilled holes

– Connectors not completely pressed into the backplane

– Titled connectors, (one side of the connector inserted more than the otherside)